printed circuit board manufacturerss be used in high-frequency applications

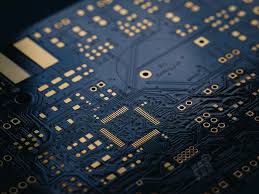

Printed Circuit Boards (PCBs) have long been integral components in electronic devices, facilitating the transmission of electrical signals between components. While traditionally associated with low-frequency applications, advancements in technology have expanded the capabilities of PCBs, enabling their use in high-frequency applications. The question arises: Can printed circuit board manufacturers be used in high-frequency applications?

The answer is a definitive yes. printed circuit board manufacturers have developed specialized techniques and materials to meet the demanding requirements of high-frequency applications. High-frequency PCBs are designed to minimize signal loss, impedance mismatch, and electromagnetic interference, allowing for reliable transmission of signals at frequencies ranging from hundreds of megahertz to several gigahertz.

One of the key considerations in designing PCBs for high-frequency applications is the selection of materials with suitable electrical properties. High-frequency PCBs typically use materials with low dielectric constants and low loss tangents to minimize signal attenuation and distortion. Common materials used in high-frequency PCBs include FR-4, PTFE (polytetrafluoroethylene), and Rogers RO4000 series laminates, each offering different characteristics tailored to specific frequency ranges and performance requirements.

Can printed circuit board manufacturerss be used in high-frequency applications?

Moreover, the layout and design of high-frequency PCBs play a critical role in their performance. Signal traces must be carefully routed to minimize impedance variations, signal reflections, and crosstalk. Ground planes and signal isolation techniques are used to reduce electromagnetic interference and maintain signal integrity. Advanced design software and simulation tools allow designers to optimize the layout and performance of high-frequency PCBs before fabrication.

In addition to materials and design considerations, printed circuit board manufacturers employ specialized fabrication techniques to produce high-frequency PCBs with tight tolerances and precise feature sizes. Advanced processes such as controlled impedance routing, laser drilling, and sequential lamination enable manufacturers to achieve the required electrical characteristics and performance specifications for high-frequency applications.

High-frequency PCBs find applications in a wide range of industries, including telecommunications, aerospace, defense, and wireless technology. In telecommunications, high-frequency PCBs are used in base stations, antennas, and communication infrastructure to transmit and receive signals over long distances. In aerospace and defense, high-frequency PCBs are employed in radar systems, satellite communications, and electronic warfare equipment to support mission-critical operations.

Furthermore, the proliferation of wireless technology has driven the demand for high-frequency PCBs in consumer electronics such as smartphones, tablets, and wireless routers. These devices rely on high-frequency PCBs to enable wireless connectivity, data transmission, and signal processing, allowing users to stay connected and access information seamlessly.

Despite their advanced capabilities, designing and manufacturing high-frequency PCBs pose unique challenges compared to traditional PCBs. High-frequency signals are more susceptible to impedance mismatches, signal loss, and electromagnetic interference, requiring careful attention to detail and rigorous testing to ensure optimal performance.

In conclusion, printed circuit board manufacturers play a crucial role in the development and production of high-frequency PCBs for a variety of applications. By leveraging specialized materials, design techniques, and fabrication processes, manufacturers can produce high-quality PCBs capable of meeting the demanding requirements of high-frequency applications. As technology continues to evolve, the demand for high-frequency PCBs is expected to grow, driving further innovation and advancement in the field of printed circuit board manufacturing.